Optical technologies enabling fusion ignition at the National Ignition Facility

Optical technologies enabling fusion ignition at the National Ignition Facility

Becky Bosco, Senior Director of Corporate Communications, Optica

The 2023 Optical Fabrication and Testing Topical Meeting (OF&T) met in Québec City, Canada, as a part of Optica’s Design and Fabrication Congress to convene on new concepts and emerging applications in optics manufacturing and metrology. Hot topics of the fabrication of optics by lasers, additive manufacturing of optical components, molding of micro-optics, deterministic manufacturing of aspheric/conformal/freeform optics, advanced metrology systems, and direct slope/curvature measurement, fabrication of optics from novel materials, efficient manufacturing, and testing of large optics.

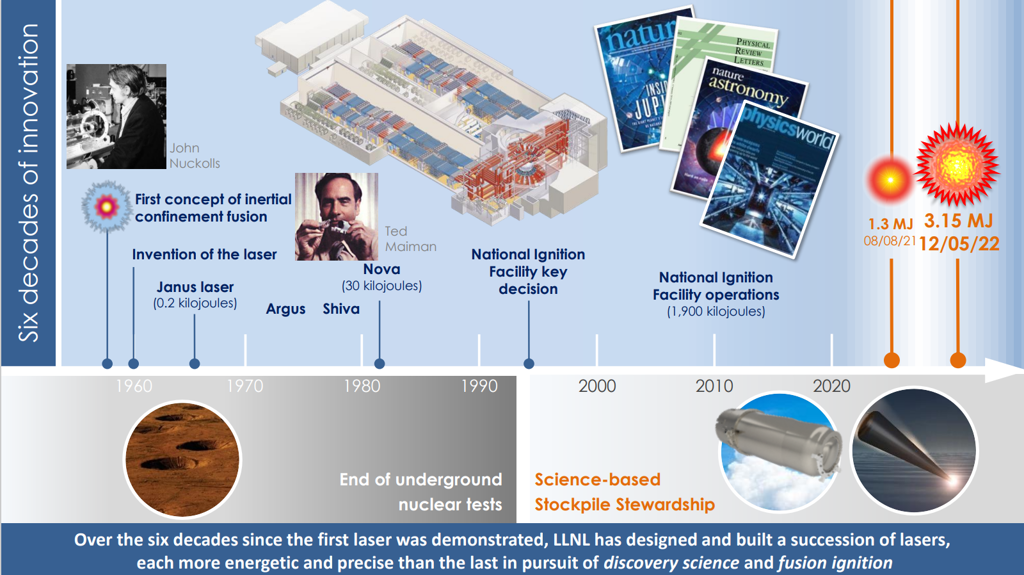

Optica Fellow, Dr. Tayyab Suratwala, program director for Optics and Materials Science and Technology (OMST), Lawrence Livermore National Laboratory (LLNL), United States. Seats were filled to hear Suratwala’s keynote presentation on the optical technologies behind one of the most notable scientific breakthroughs in decades. On 5 December 2022, Lawrence Livermore National Laboratory’s National Ignition Facility conducted the first successful controlled fusion experiment to achieve fusion ignition. Also known as scientific energy breakeven, the experiment produced more energy from fusion than the laser energy used to drive it– with 3.15 MJ of fusion output for 2.05 MJ laser delivered.

Six decades of innovation

In the 1960s, pioneering scientists at LLNL hypothesized that lasers could induce fusion in a laboratory setting. Led by physicist John Nuckolls, who later served as LLNL director from 1988 to 1994, this revolutionary idea became inertial confinement fusion, kicking off more than 60 years of research and development in lasers, optics, diagnostics, target fabrication, computer modeling and simulation and experimental design.

To pursue this research, LLNL built a series of increasingly powerful laser systems, leading to the creation of NIF, the world’s largest and most energetic laser system. NIF — located at LLNL in Livermore, California — is the size of a sports stadium and uses powerful laser beams to create temperatures and pressures like those in the cores of stars and giant planets, and inside exploding nuclear weapons. Suratwala’s presentation detailed how NIF’s high power and energy lasers demand optics with greater precision, functionality, and survivability.

Fusion ignition: Enabled by optics

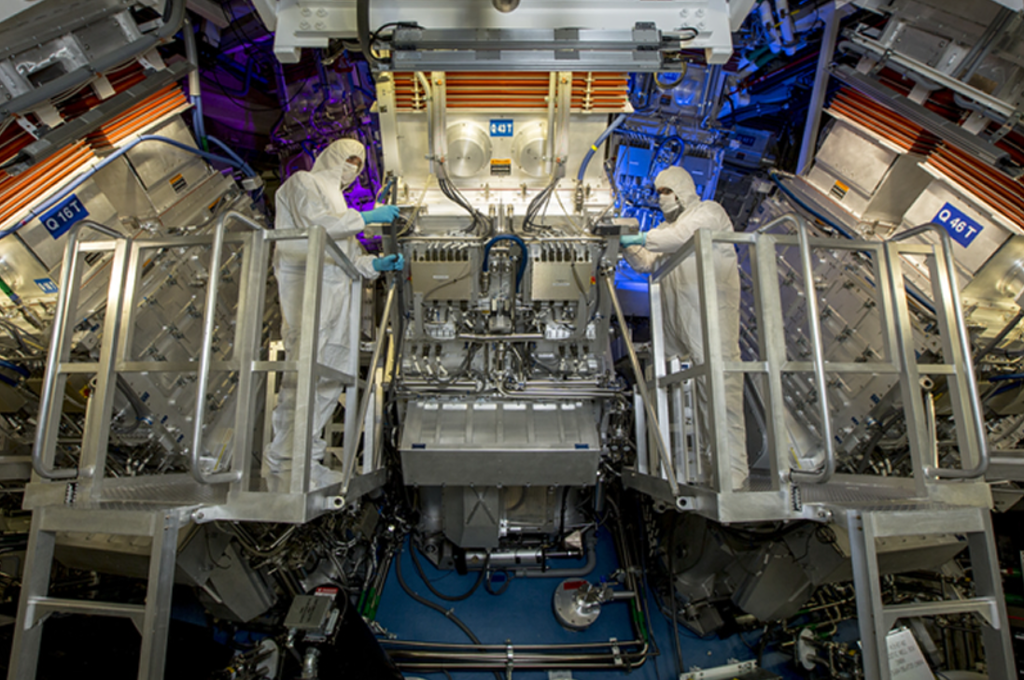

Optical technologies have not just enabled NIF successfully operate, but also continually increase shot rate and energy and power. “NIF contains >7,000 large optics,” explained Suratwala. “NIF has had multi-decade partnerships with the large-aperture precision optics industry, from Hoya, Schott, Gooch & Housego, Coherent, Zygo, L3Harris and Spectra Physics, to name a few.”

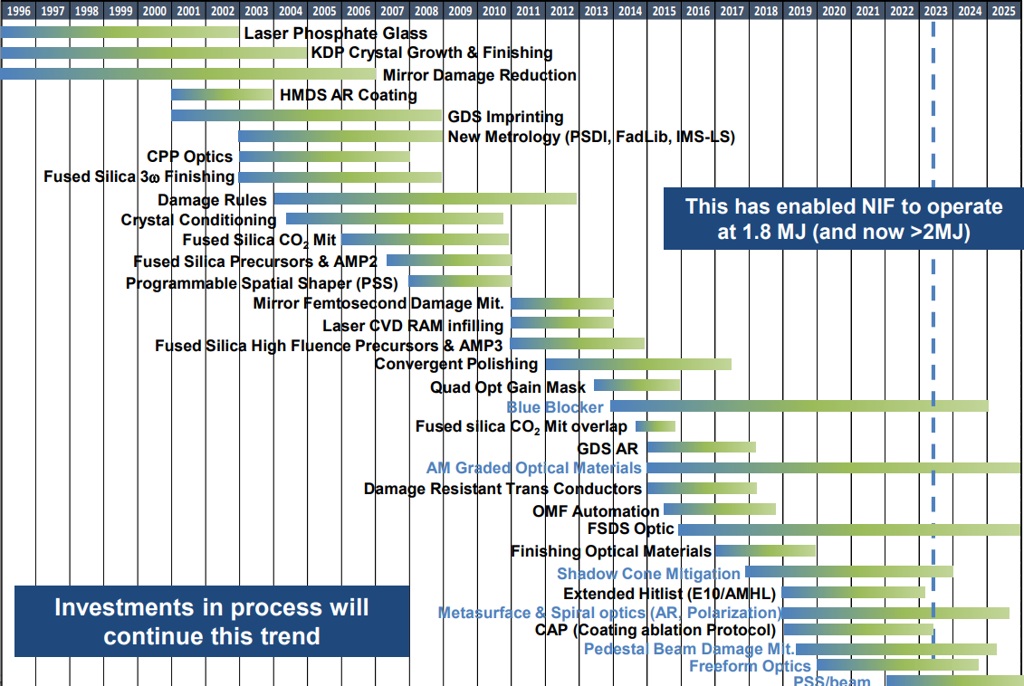

To keep NIF in a state of continuous operation and testing, Suratwala’s team has developed a robust system of keeping the optics in good function by routinely recycling some of them to repair any laser damage, at a small fraction of the cost and time for obtaining a new optic. NIF’s optics are routinely tested, removed, repaired, and cleaned on-site. At the same time, the team experiments with new fabrication and processing methods to enable higher optic laser damage resistance, and therefore greater NIF energy and power. Suratwala explained, “A 20 year- long science and technology investment has enabled transitioning optical fabrication and processing from an ‘art’ to more of a science. Tremendous progress has been made in improving the damage resistance of as-fabricated fused silica optics.”

“Managing NIF optics damage is like peeling a growing onion…as challenges are mitigated, new challenges arise with increased power and energy,” said Suratwala. “NIF final optics quality and configuration has evolved leading to reduction in laser damage. We’ve also found success with novel production level metrologies to ensure high quality of the delivered precision optics.”

The history of Optics and Materials Science and Technology at NIF

Tayyab has been working on the NIF since its construction started in 1997. “I feel fortunate to be working on a team going after big science and technology for the last 26 years. I highly encourage next generation optical scientists/engineers to participate in such big science projects; it has the unique balance of the technology/engineering drive focused in industry combined with the fundamental science progress in academia.”