Researchers leverage inkjet printing to make a portable multispectral 3D camera

About Optica

12 June 2024

Researchers leverage inkjet printing to make a portable multispectral 3D camera

Palm-sized light field camera could improve autonomous driving, classification of recycled materials and remote sensing

Caption: Researchers used inkjet printing to create a multispectral version of a light field camera, which fits in the palm of the hand. The 3D camera could be useful for applications such as autonomous driving, classification of recycled materials and remote sensing.

Credit: Maximilian Schambach, Karlsruhe Institute of Technology

WASHINGTON — Researchers have used inkjet printing to create a compact multispectral version of a light field camera. The camera, which fits in the palm of the hand, could be useful for many applications including autonomous driving, classification of recycled materials and remote sensing.

3D spectral information can be useful for classifying objects and materials; however, capturing 3D spatial and spectral information from a scene typically requires multiple devices or time-intensive scanning processes. The new light field camera solves this challenge by simultaneously acquiring 3D information and spectral data in a single snapshot.

“To our knowledge, this is the most advanced and integrated version of a multispectral light field camera,” said research team leader Uli Lemmer from the Karlsruhe Institute of Technology in Germany. “We combined it with new AI methods for reconstructing the depth and spectral properties of the scene to create an advanced sensor system for acquiring 3D information.”

In the Optica Publishing Group journal Optics Express, the researchers report that the new camera and image reconstruction methods can be used to distinguish objects in a scene based on their spectral characteristics. Using inkjet printing to make the camera’s key optical components allows it to be easily customized or manufactured in large volumes.

“Reconstructed 3D data from camera images are finding widespread use in virtual and augmented reality, autonomous cars, robotics, smart home devices, remote sensing and other applications,” said Michael Heizmann, a member of the research team. “This new technology could, for example, allow robots to better interact with humans or improve the accuracy of classifying and separating materials in recycling. It could also be potentially used to classify healthy and diseased tissues.”

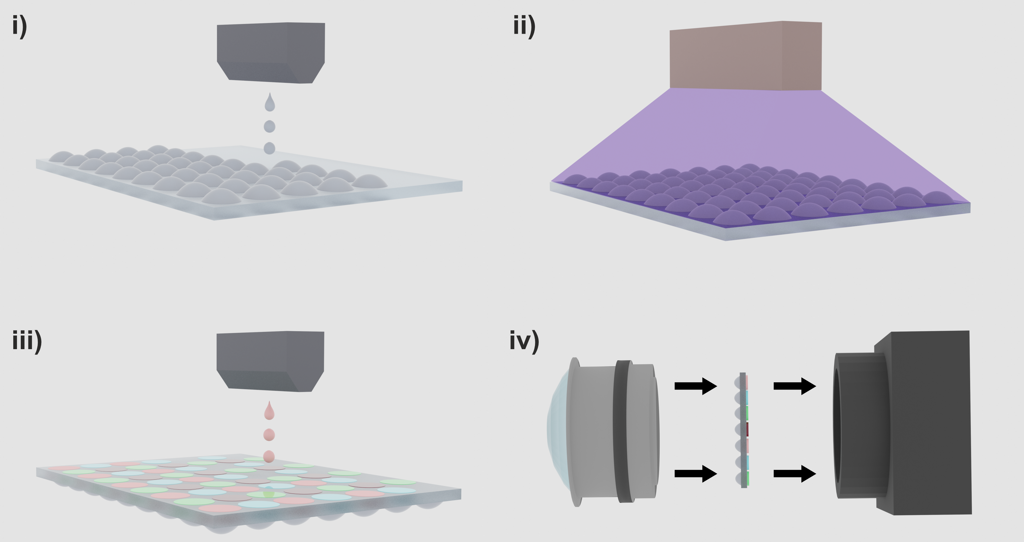

Caption: Inkjet printing was used to deposit single droplets of material to form individual lenses on one side of ultrathin microscope slides (i). After curing (ii), fully aligned color filter arrays were printed on the opposite side of the microscope slides (iii). The resulting optical component was integrated directly onto a CMOS camera chip and placed in a camera housing (iv).

Credit: Qiaoshuang Zhang, Karlsruhe Institute of Technology

Adding color with inkjet printing

Light field cameras, also called plenoptic cameras, are specialized imaging devices that capture the direction and intensity of light rays. After image acquisition, computational processing is used to reconstruct 3D image information from the acquired data. These cameras typically use microlens arrays that are aligned with the pixels of a high-resolution camera chip.

To create a multispectral light field camera, the researchers used inkjet printing to deposit a single droplet of material to form each individual lens on one side of ultrathin microscope slides and then printed fully aligned color filter arrays on the opposite side of the microscope slides. The resulting optical component was integrated directly onto a CMOS camera chip. The inkjet printing method allowed precise alignment between the optical components, significantly reducing the manufacturing complexity and enhancing efficiency.

Because this setup produces spectral and depth information that are interwoven in the camera image, the researchers developed methods to separate each component. They found that an approach based on deep learning worked best for extracting the desired information directly from the acquired measurements.

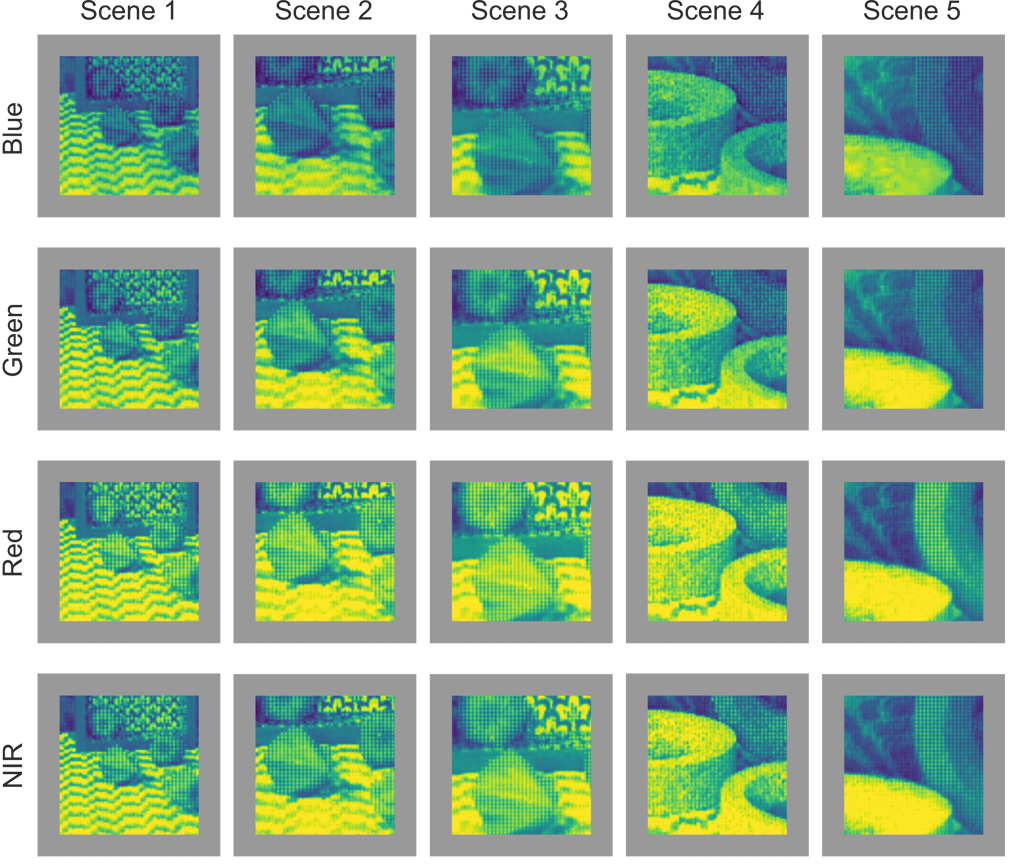

Caption: The researchers used the new camera and deep-learning method to produce these reconstructed views in different color channels (false-color representation).

Credit: Maximilian Schambach, Karlsruhe Institute of Technology

Spectral-based object detection

“Tackling the challenge of creating a multispectral light field camera was only possible by combining recent advances from manufacturing, system design and AI-based image reconstruction,” said Qiaoshuang Zhang, first author of the paper. “This work pushes the boundaries of inkjet printing — a versatile method with high precision and industrial scalability — for manufacturing photonic components.”

The researchers tested the camera by recording a test scene that contained multicolor 3D objects at different distances. The image reconstruction algorithm was trained and tested on many synthetic and real multispectral images. The results demonstrate that the prototype camera can simultaneously acquire 3D spatial and spectral information and that different objects can be imaged and distinguished by their different spectral composition and depth information within one single snapshot.

Now that they have completed this first proof-of-concept, the researchers are exploring various applications where a light field camera with an ability to acquire multispectral information could be useful.

Paper: Q. Zhang, M. Schambach, Q. Jin, M. Heizmann, U. Lemmer, “Compact multispectral light field camera based on an inkjet-printed microlens array and color filter array,” Opt. Express, Vol. 32, Issue 13, pp. 23510-23523 (2024).

Caption: The Karlsruhe Institute of Technology team is shown with inkjet-printed color filters.

Credit: Jan Feßler, Karlsruhe Institute of Technology

DOI: doi.org/10.1364/OE.521646

About Optica Publishing Group

Optica Publishing Group is a division of the society, Optica, Advancing Optics and Photonics Worldwide. It publishes the largest collection of peer-reviewed and most-cited content in optics and photonics, including 18 prestigious journals, the society’s flagship member magazine, and papers and videos from more than 835 conferences. With over 400,000 journal articles, conference papers and videos to search, discover and access, our publications portfolio represents the full range of research in the field from around the globe.

About Optics Express

Optics Express reports on scientific and technology innovations in all aspects of optics and photonics. The bi-weekly journal provides rapid publication of original, peer-reviewed papers. It is published by Optica Publishing Group and led by Editor-in-Chief James Leger of the University of Minnesota, USA. Optics Express is an open-access journal and is available at no cost to readers online. For more information, visit Optics Express.

Media Contact