Researchers Develop Laser-Based Process to 3D Print Detailed Glass Objects

About Optica

12 January 2021

Researchers Develop Laser-Based Process to 3D Print Detailed Glass Objects

Multiphoton polymerization approach might one day be used to print complex optics

WASHINGTON — Researchers have developed a new laser-based process for 3D printing intricate parts made of glass. With further development, the new method could be useful for making complex optics for vision, imaging, illumination or laser-based applications.

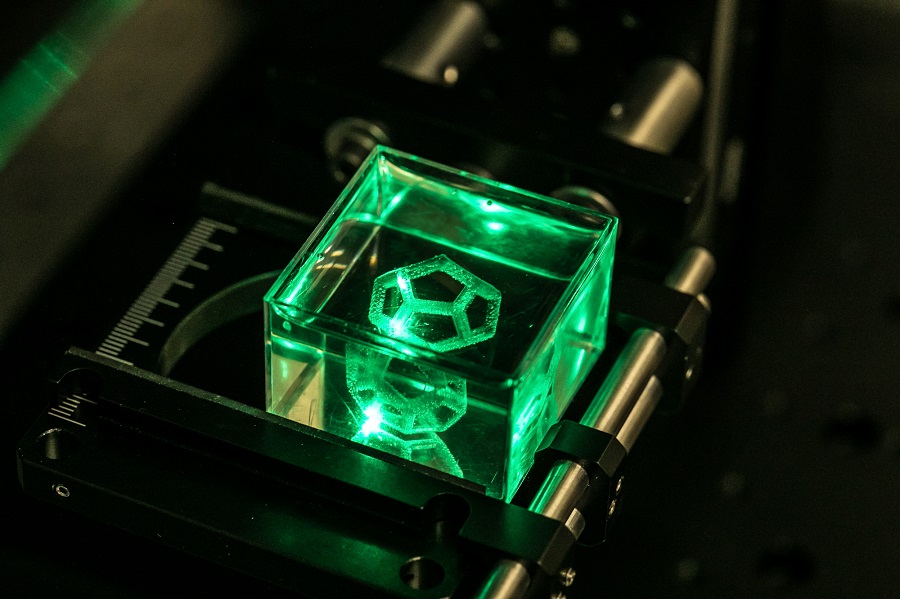

Caption: Researchers have developed a new laser-based process for 3D printing intricate parts made of glass. It uses multiphoton polymerization to create an object directly in a 3D volume.

Credit: Laurent Gallais, The Fresnel Institute and Ecole Centrale Marseille

“Most 3D printing processes build up an object layer by layer,” said research team leader Laurent Gallais from The Fresnel Institute and Ecole Centrale Marseille in France. “Our new process avoids the limitations of these processes by using a laser beam to transform -- or polymerize -- a liquid precursor into solid glass.”

In The Optical Society (OSA) journal Optics Letters, Gallais and research team members Thomas Doualle and Jean-Claude Andre demonstrate how they used the new technique to create detailed objects in a 3D volume without using the classical layer-by-layer approach. Using this approach, they created a variety of silica glass objects such as miniature models of a bike and the Eiffel Tower without any pores or cracks.

The 3D printing approach is based on multiphoton polymerization, which ensures that polymerization, a process that links liquid monomer molecules together into a solid polymer, only takes place at the precise laser focal point. It allows direct fabrication of 3D parts that range in size from a few microns to tens of centimeters with a resolution that is theoretically only limited by the optics used for laser beam shaping.

“Glass is one of the primary materials used to make optics,” said Gallais. “Our work represents a first step toward developing a process that could one day allow scientists to 3D print the optical components they need.”

Finding the right material

Using a traditional layer-by-layer approach to build 3D glass objects comes with several limitations. The speed of the printing process is limited by the time it takes to build the layers, and it can be difficult to create layers with consistent thicknesses when using highly viscous resins. Making complex parts typically requires supports, which must be precisely positioned and then removed once the object hardens.

Caption: The new approach can be used to make a variety of complex objects such as the bicycle and Eiffel Tower shown here.

Credit: Laurent Gallais, The Fresnel Institute and Ecole Centrale Marseille

Although multiphoton polymerization can be used to avoid the layer-by-layer approach, 3D printing glass objects requires a material that is transparent at the wavelength of the laser both during the initial liquid phase and once polymerized. It must also absorb the laser light at half the laser wavelength to initiate the multiphoton polymerization process.

To accomplish this, the researchers used a mixture containing a photochemical initiator to absorb the laser light, a resin and high concentration of silica nanoparticles. In addition to working well with the laser, this mixture’s high viscosity allows a 3D part to be formed without deformation problems or supports to keep the object in place during 3D printing.

“Critical to the technique were high power ultrashort lasers based on Strickland and Mourou’s chirped pulse amplification technology recognized with a Nobel prize in 2018,” said Gallais. “Only intense and very short pulses will create non-linear photo polymerization with high precision and no thermal effects.”

Testing the process

After validating that a solid object could be created using the silica nanoparticle mixtures, the researchers used their 3D printing approach to create objects with complex shapes. They also applied a process that transforms the polymerized parts into glass.

“Our approach could potentially be used to produce almost any type of 3D glass object,” said Gallais. “For example, we are exploring the possibility of producing glass parts that could be used on luxury watches or perfume bottles.”

Caption: The video shows a laser being used to polymerize a liquid containing silica nanoparticles to create a miniature glass bicycle.

Credit: Laurent Gallais, The Fresnel Institute and Ecole Centrale Marseille

The researchers are working to make the technique more practical and reduce cost by experimenting with less expensive laser sources, for example. They also want to optimize the process to improve the surface quality to decrease roughness.

Paper: T. Doualle, J.-C. Andre, L. Gallais, “3D-printing of silica glass through multiphoton polymerization process,” Opt. Lett., 46, 2, 364-367 (2021).

DOI: https://doi.org/10.1364/OL.414848.

About Optica Publishing Group

Optica Publishing Group is a division of the society, Optica, Advancing Optics and Photonics Worldwide. It publishes the largest collection of peer-reviewed and most-cited content in optics and photonics, including 18 prestigious journals, the society’s flagship member magazine, and papers and videos from more than 835 conferences. With over 400,000 journal articles, conference papers and videos to search, discover and access, our publications portfolio represents the full range of research in the field from around the globe.

About Optics Letters

Optics Letters has been publishing high-impact research in the field of photonics for over 45 years and offers rapid dissemination of new results in all areas of optical science with short, original, peer-reviewed communications. Optics Letters accepts papers that are noteworthy to a substantial part of the optics community. Published by Optica Publishing Group and led by Editor-in-Chief Miguel Alonso, Institut Fresnel, École Centrale de Marseille and Aix-Marseille Université, France, University of Rochester, USA. For more information, visit Optics Letters.

About The Optical Society

The Optical Society (OSA) is dedicated to promoting the generation, application, archiving, and dissemination of knowledge in optics and photonics worldwide. Founded in 1916, it is the leading organization for scientists, engineers, business professionals, students, and others interested in the science of light. OSA’s renowned publications, meetings, online resources, and in-person activities fuel discoveries, shape real-life applications and accelerate scientific, technical, and educational achievement.

About Optics Letters

Optics Letters has been publishing high-impact research in the field of photonics for over 45 years and offers rapid dissemination of new results in all areas of optical science with short, original, peer-reviewed communications. Optics Letters accepts papers that are noteworthy to a substantial part of the optics community. Published by Optica Publishing Group and led by Editor-in-Chief Miguel Alonso, Institut Fresnel, École Centrale de Marseille and Aix-Marseille Université, France, University of Rochester, USA. For more information, visit Optics Letters.

Media Contact