About

10 April 2024

From battery cells to cars, Luxinar's lasers drive e-mobility innovation

Leading laser manufacturer Luxinar is showcasing its laser applications for every step of the battery production process, from cell to car, at The Battery Show Europe. CO2 laser sources and femtosecond lasers that can shape battery cells and refine electronic components will be presented for the first time on stand 4-G58 from 18 to 20 June in Stuttgart, Germany.

Luxinar’s battery cell applications include cutting separator foils and cutting and notching electrodes. Battery module and power train applications comprise e-vehicle battery casing ablation and busbar isolation stripping and trimming, and e-mobility applications include electric motor hairpin coating removal. We outline below one of the many ways that lasers can contribute to battery manufacturing and carbon footprint reduction.

Unwrapping non-conforming or used prismatic battery cells by laser

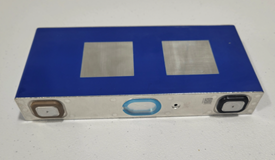

Prismatic cells in automotive applications are frequently wrapped in a self-adhesive PET heat shrink film. This film might need selective removal to add heat management components to the bare metal of the can or complete removal to rework non-conforming cells in the production cycle. Finally, when the battery is recycled at the end of its life, the film needs to be removed.

Currently, most of the above processes are done manually by cutting the foil with knives and scraping it off before wiping off the residues with solvents. This mechanical and chemical process leaves a clean but scratched surface.

Moving over to non-contact laser processing allows partial or full automation of the process and handling cells of different shapes and sizes in high volumes. A Luxinar OEM 45iX CO2 laser source ablates the film and leaves an invisible and very thin layer of sticky residue on the bare metal surface, needing post-process treatment. However, the residue can be removed by simply wiping with isopropanol, so the laser process removes the need for harsh solvents and intensive mechanical effort.

Christian Dini, Commercial Manager – Central & Northern Europe of Luxinar, stated: “We are thrilled to be showcasing our laser sources for the first time at The Battery Show Europe. Luxinar has been mastering lasers since 1998, and the versatility and precision of our laser technology make various battery production tasks economically viable."

About Luxinar

At Luxinar, we have a singular focus: developing laser technology to enhance our world.

Like a laser that channels light into a single, powerful beam, we focus on improving the lives of our customers. This allows us to create solutions to meet every single challenge – from heavy industry to delicate, high precision applications. We support the laser technologies of yesterday, focus on today’s and pioneer those of tomorrow.

Luxinar has been at the forefront of laser technology for over 25 years and is a leading manufacturer of sealed carbon dioxide (CO2) laser sources up to 1000W and ultrashort pulse laser sources. To date, we have an installed base of over 25000 lasers worldwide.

Luxinar Ltd

Meadow Road

Bridgehead Business Park

Kingston Upon Hull

HU13 0DG, UK

Joanna Houldridge

+44 (0)1482 650088