Mangirdas Malinauskas

Laser Research Center at Vilnius University, LithuaniaFor advancing ultrafast laser 3D lithography and pioneering work towards applying it for micro-optics and biomedical scaffolds.

Mangirdas Malinauskas was destined to be a scientist from the moment his parents named him. In Lithuanian, "Mangirdas" is composed of two words: "man," which means "to me," and "girdas," which means "to listen." Together, they literally mean "to listen to myself," but a more poetic translation is "One who wants to know" or to understand. He recalls that as a child, he would read the encyclopedia with great interest, eager to learn more about the world. He found lasers during his undergraduate studies, observing that they were a perfect tool to understand nonlinear phenomena, a subject that interested him due to its mystery.

Today, Mangirdas works in multiphoton lithography, or laser nonlinear lithography, which is essentially 3D printing using lasers. He shares, "I'm employing nonlinear light matter interaction and aiming to process almost any kind of materials from polymers to ceramics, even metals." His biggest challenge right now is that the field is growing rapidly, making keeping up with every new development nearly impossible. It can also be difficult for young researchers to make their mark in such an ever-changing landscape. He encourages his own students to stick to their area and that progress will follow with dedication.

Dedication is exactly how Mangirdas was able to create such a fulfilling career for himself. He shares that he was perhaps not the best student at times in school, but he continued to work hard and follow his interests in the field. His personal motto guides him: "Direction is more important than speed." He has stayed focused on the research areas that interested him at the start of his career and still enjoys his work.

Mangirdas is most excited about the balance of research and applications that he is experiencing in the field right now. His specific work in revealing wavelengths for 2-photon polymerization is at the forefront of extending the technique and enabling new applications, and he feels happy to contribute to the field's growth. He shares that 3D printing is entering nearly all other fields, from house building and food preparation to manufacturing, electronics, and medicine. An enabling technology, the better and more precise 3D printing can become, the faster other fields can utilize the technology for their own developments. The possibilities, especially now, are endless.

Throughout his career, Mangirdas has had the support of many wonderful mentors, many of whom are now collaborators and colleagues. Alexandr Ovsianikov, Carsten Reinhard, and Boris Chichkov were instrumental early on in Mangirdas’ career, introducing him to new ideas and shaping his interests. Professor Saulius Juodkazis wrote a paper that Mangirdas was interested in nearly 20 years ago. Taking the initiative, Mangirdas wrote to Saulius, and the two have collaborated ever since. A similar story happened when Mangirdas met Maria Farsari at a summer school. The two have several projects together, and their students frequently visit each other's labs. Mangirdas encourages his students to connect with other researchers, like he did, to start building relationships with people whose work interests them. In his experience, people are happy to talk about their work and hear about other perspectives.

Mangirdas' election to Optica Fellow came at a particularly relevant year. The 2023 President, Satoshi Kawata, is an originator of the field in which Mangirdas has built a career. Satoshi's first paper on the topic, "Three-dimensional microfabrication with two-photon-absorbed photopolymerization," was published in Optics Letters in 1997. This opening of a new direction was notable to Mangirdas, who has followed Shatoshi's work ever since. The honor was even more impactful when the Optica Fellow notification arrived with Satoshi's signature.

Photo Credit: Mangirdas Malinauskas

Profile written by Samantha Hornback

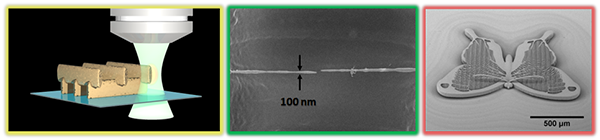

Above: Multi-photon lithography principle and produced exemplar structures (from left to right):

- laser direct writing 3D multi-photon lithography process.

- nanoscale features (suspended line) produced out of plant-based resin.

- a multi-scale butterfly manufactured using continuous writing approach out of SZ2080TM hybrid material.