About

04 November 2019

New Technology Poised to Lower Cost and Expand Applications for Transparent LED Screens

For the first time, transparent conductive circuits made of silver nanowires used to make rigid and flexible transparent displays

WASHINGTON — Connecting LEDs with transparent conductive circuits has made it possible to turn glass windows, walls and building exteriors into see-through displays that inform or entertain viewers with videos and images. A new approach to making these circuits could help lower the costs of transparent LED screens and allow the technology to be used on substrates that are flexible or curved.

In The Optical Society (OSA) journal Optical Materials Express, researchers from Zhejiang University in China and the KTH Royal Institute of Technology in Sweden report fabrication of meter-scale transparent conductive circuits based on silver nanowire networks, and, for the first time, demonstrate these circuits in both rigid and flexible transparent LED screens.

“Transparent LED screens act much like traditional LCDs or LED televisions but the fact that they don’t block light enables creative applications not possible with conventional display technology,” said Liu Yang, who led the Zhejiang University research team. “The circuits we fabricated are highly transparent, conductive and flexible, and thus are very promising as a replacement for transparent circuits used today.”

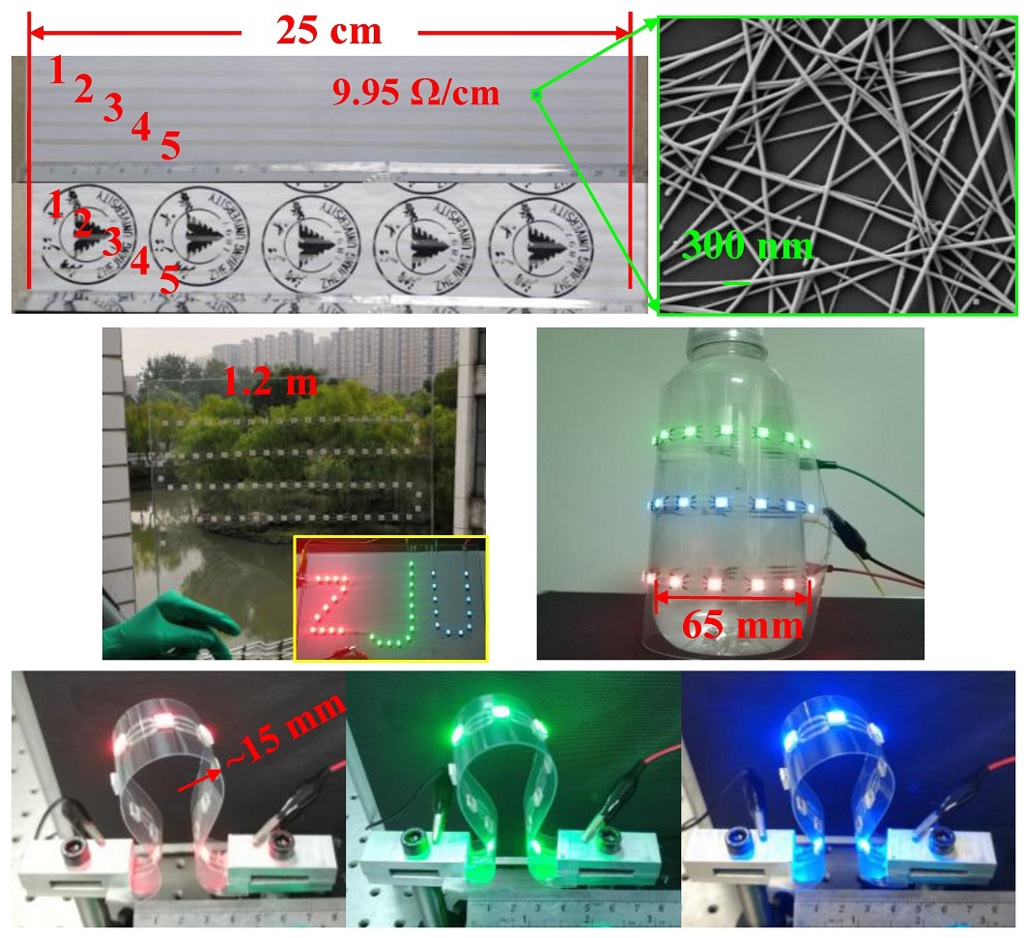

Caption: Researchers demonstrate rigid and flexible transparent LED screens based on their new silver nanowire transparent conductive circuits.

Credit: Liu Yang, Zhejiang University

Replacing today’s transparent circuits

Transparent LED displays typically incorporate transparent conductive circuits made from fluorine-doped tin oxide (FTO) or indium tin oxide (ITO). Scientists have been looking for alternatives to these materials because of indium’s high cost and the complex and expensive manufacturing process necessary to create circuits for large-format transparent displays. In addition, circuits made from ITO and FTO tend to be too brittle for flexible applications.

Silver nanowire networks are a promising replacement because silver nanowires can be easily synthesized and distributed over a large area, have excellent optical transparency, are highly conductive and can bend without breaking or compromising performance. Although silver nanowire networks have been used to create transparent conductive films, using them to make long circuits has proved challenging.

In the new work, the researchers developed a straightforward fabrication process for using silver nanowires to make the ultralong transparent circuits necessary for meter-scale transparent LED screens. Using a spray coating method and sacrificial masks, they created a 1.2-meter silver nanowire transparent conductive circuit.

The new transparent conductive circuits consist of randomly distributed silver nanowires that are applied in a pattern to a substrate such as plastic or glass. The nanowire network must be dense enough for the electrical current to travel well but not so dense as to compromise transparency.

“Because of our very simple and low-cost fabrication method and the inherent flexibility of silver nanowires, these new transparent conductive circuits could lower the cost and expand the applications of the transparent LED screens to flexible and large-angle curved areas,” said Yang.

Testing see-through displays

Analysis of the silver nanowire circuits showed that they were highly transparent while exhibiting higher conductivity than ITO. The researchers also performed tests in which they bent silver nanowire conductive strips and ITO transparent strips deposited on a plastic film to a radius as small as 2 millimeters. The silver nanowire strip showed mechanical flexibility and stable performance during the bending tests while ITO didn’t maintain performance.

Next, the researchers incorporated the sliver nanowire transparent conductive circuits into prototype LED displays with glass or plastic substrates. These included a plastic display that performed well even when wrapped around a small bottle or dynamically bent to a radius as small as about 15 millimeters.

The researchers point out that just a few simple steps could turn their prototype screens into practical transparent screens. For example, the transparent conductive circuits could easily be designed to allow programming of connected LEDs for displaying videos. Also, the circuits would need to be protected with a coating to avoid chemical reactions with the environment and to enhance their adhesion to the substrates. The screens could also be integrated with sandwiched glass or transparent plastic films for further protection and easy maintenance.

Paper: L. Yang, X. Xu, Y. Yuan, Z. Li, S. He, “Meter-scale transparent conductive circuits based on silver nanowire networks for rigid and flexible transparent light-emitting diode screens,” Opt. Mater. Express 9, 12, 4483-4496 (2019).

DOI: https://doi.org/10.1364/OME.9.004483.

About The Optical Society

The Optical Society (OSA) is dedicated to promoting the generation, application, archiving, and dissemination of knowledge in optics and photonics worldwide. Founded in 1916, it is the leading organization for scientists, engineers, business professionals, students, and others interested in the science of light. OSA’s renowned publications, meetings, online resources, and in-person activities fuel discoveries, shape real-life applications and accelerate scientific, technical, and educational achievement.

About Optical Materials Express

Optical Materials Express is an open-access journal focusing on the synthesis, processing and characterization of materials for applications in optics and photonics. It is published by Optica Publishing Group and emphasizes advances in novel optical materials, their properties, modeling, synthesis and fabrication techniques; how such materials contribute to novel optical behavior; and how they enable new or improved optical devices. The Editor-in-Chief is Andrea Alù from City University of New York, USA. For more information, visit Optical Materials Express.

Media Contact